HD SUPERABRASIVES

PRECISION PERFORMANCE

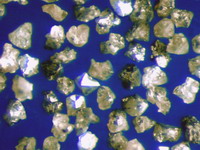

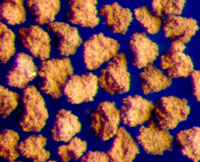

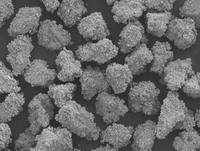

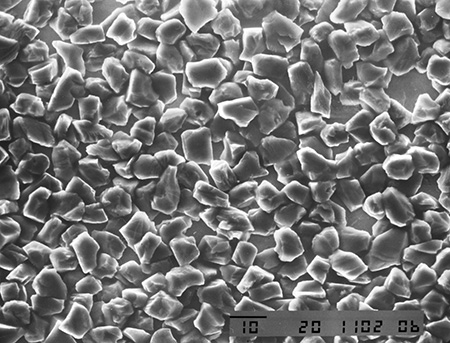

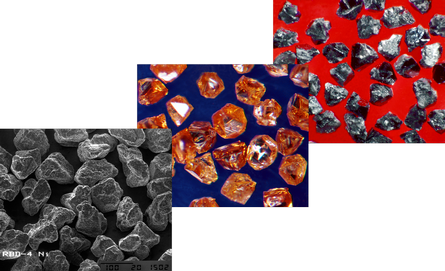

INDUSTRIAL DIAMOND POWDER

EXCELLENT RESULT ON GLASS & BIJOUTERIE

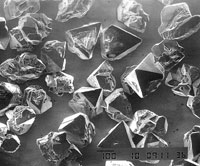

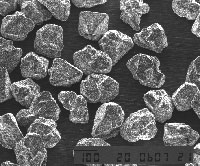

MICRON DIAMOND POWDER

Constancy Distribution Form and Size

HORIBA PARTICLE SIZE ANALYSIS

Retsch Technology calibration protocol

DIAMOND COMPOUND

DIAMOND SUSPENSION

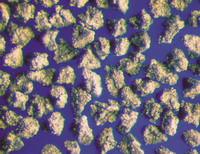

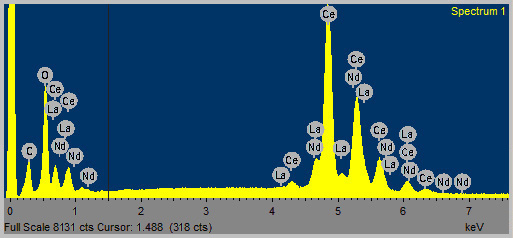

CERIUM OXIDE

POLISHING POWDER BROWN

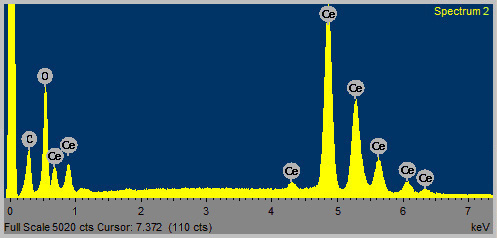

CERIUM OXIDE

POLISHING POWDER WHITE

HD SUPERABRASIVES

HIGHT QUALITY IN WORK

LABORATORY EQUIPMENT

QUALITY CONTROL