- Products

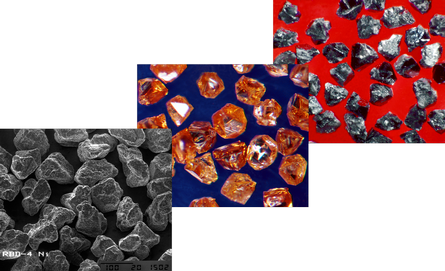

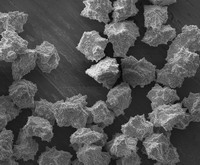

- Resin Bond Diamond series

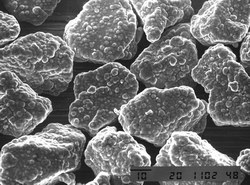

- RBD G

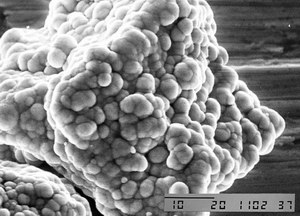

- RBD 6

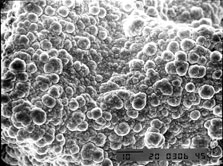

- RBD 20

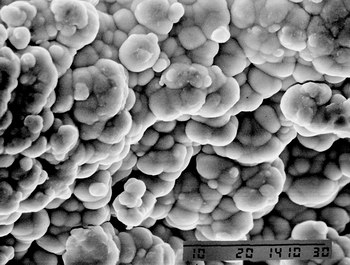

- Mosaic structure

- Metal coated abrasive for resin bond

- Table of size availability

- Catalog in PDF

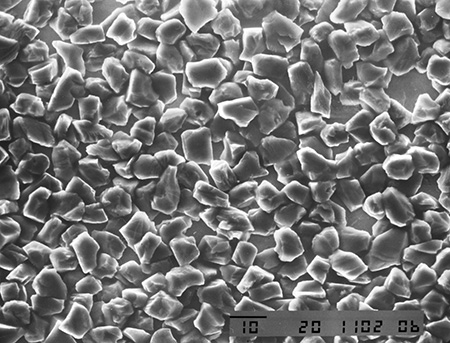

Metal coated abrasive for resin bond.

With the coating of metallized coverage on the crystals the superior adhesiveness in resin bond and better thermal characteristics are reached. Thus the offered coatings enhance the working properties of the tools.

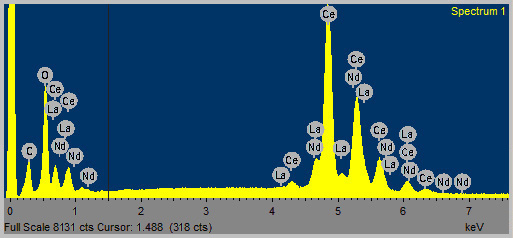

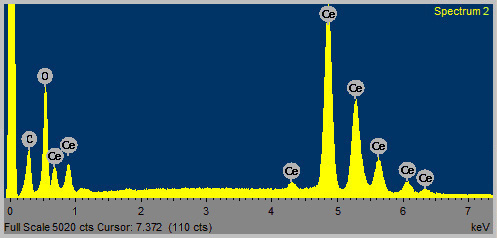

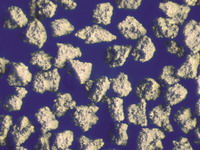

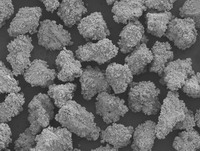

Electroless Nickel coating RBD G 56N

During the electroless nickel cladding process, the surface of crystal is catalytically activated, thus the optimum adhesion between the diamond and nickel is reached. The electroless nickel coating enhances the thermal properties of the tools. Superabrasive products are used with 56% or 60% coating of nickel alloy by total weight

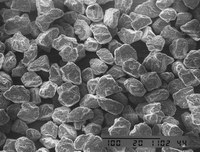

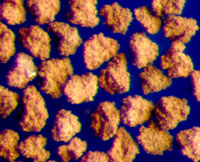

Electroless Copper coating RBD 6 50Cu

The electroless copper coating allows reaching the higher thermal conductivity and heat abstraction from the grinding zone. The tools, containing diamond powder with copper coating, are mostly used for dry grinding of cemented carbides. It is available with 50% of cooper by total weight

© 1991-2021 HD Superabrasives

All pictures and technical data used in this brochure are property of Haris Division. Unauthorized duplication is a violation of copyright law.

All pictures and technical data used in this brochure are property of Haris Division. Unauthorized duplication is a violation of copyright law.