|

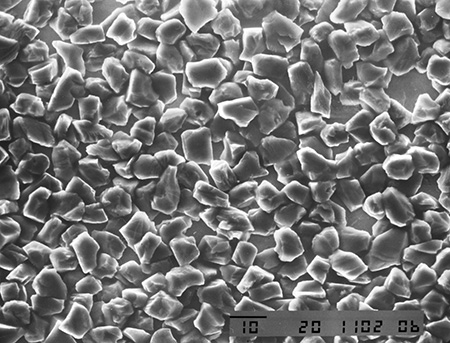

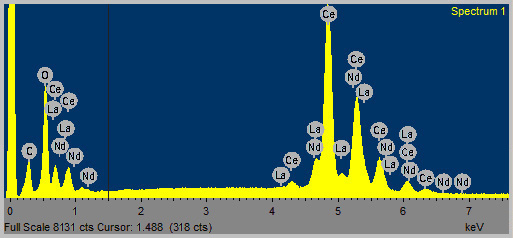

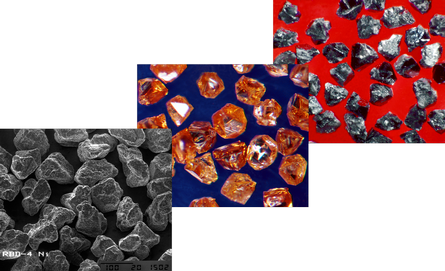

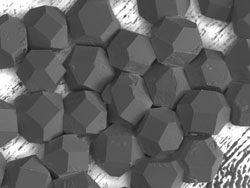

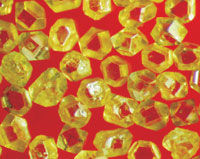

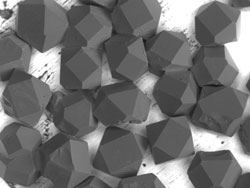

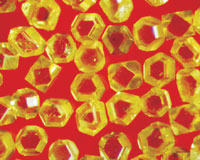

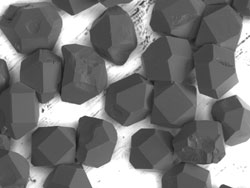

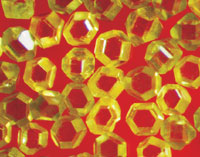

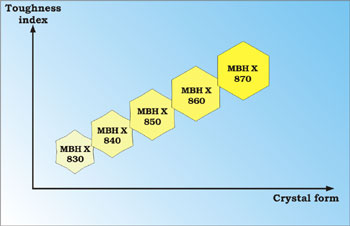

Measurement results of

strength and thermal stability of diamond powder of MBH X series, size

40/45 US mesh.

|

Type of powder |

Static

strength index,

N |

GOST 9206-80 |

Coefficient

of thermal stability |

Indicator of

thermal stability |

Index of

thermal stability

|

P, basic value- room temperature |

P, after thermotreatment |

|

MBH X 870 |

338,5 |

292,3 |

AC 200 |

0,86 |

9 |

HT |

MBH X 860 |

342,5 |

256,6 |

AC 200 |

0,75 |

8 |

HT |

MBH X 850 |

315,5 |

256,5 |

AC 200 |

0,81 |

8 |

HT |

MBH X 840 |

292,5 |

235,2 |

AC 160 |

0,80 |

8 |

HT |

MBH X 830 |

269,4 |

238,0 |

AC 160 |

0,88 |

9 |

HT |

|