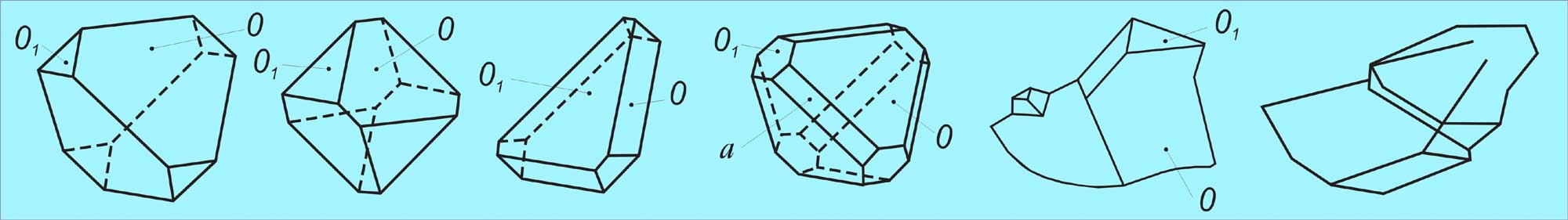

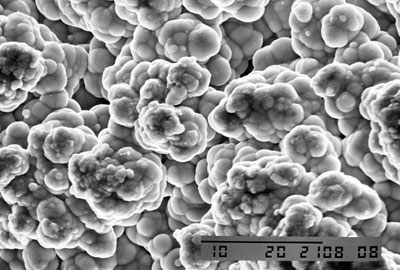

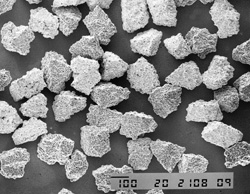

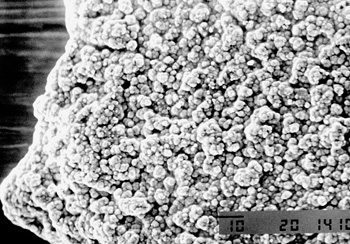

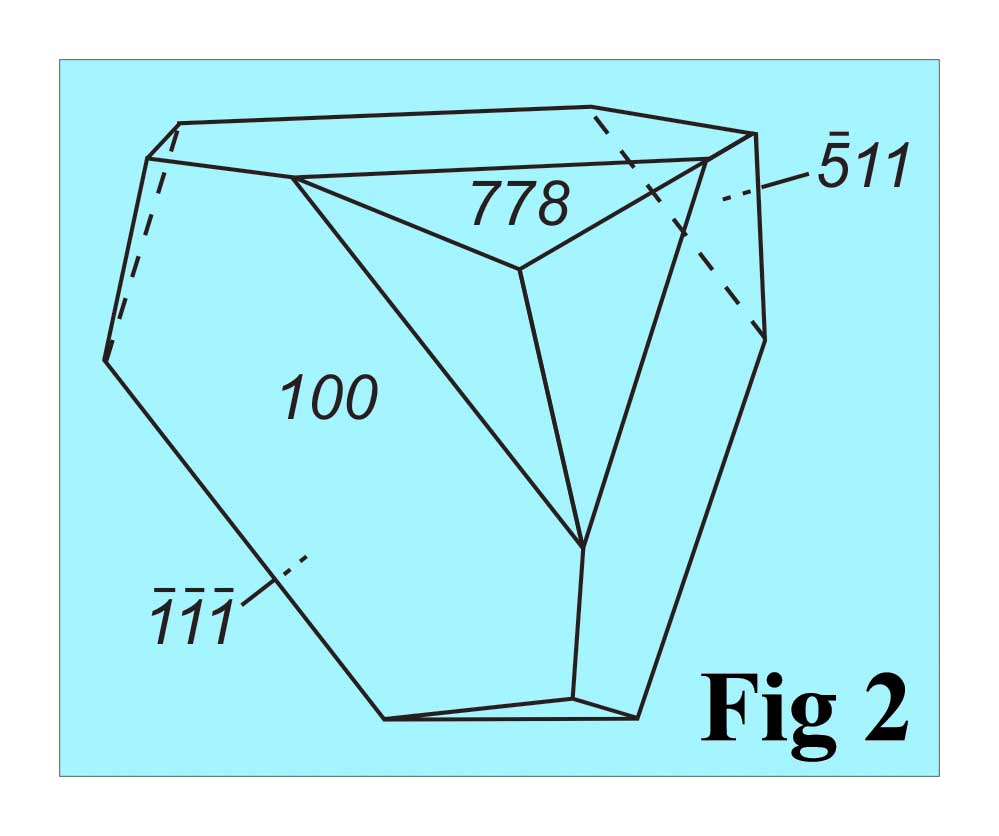

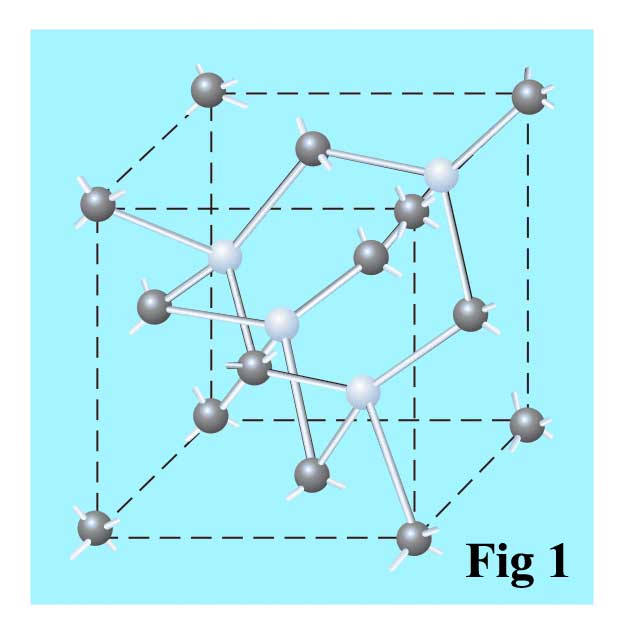

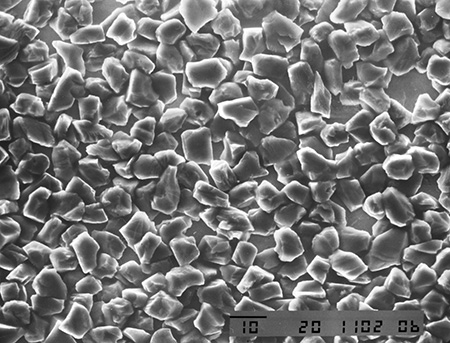

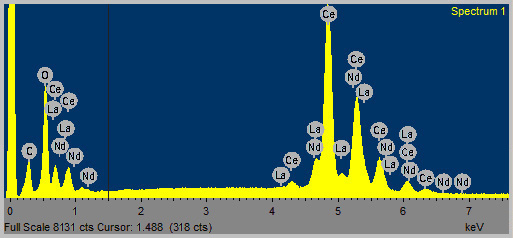

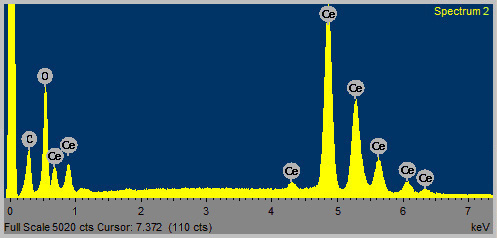

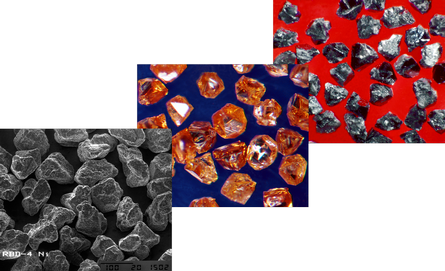

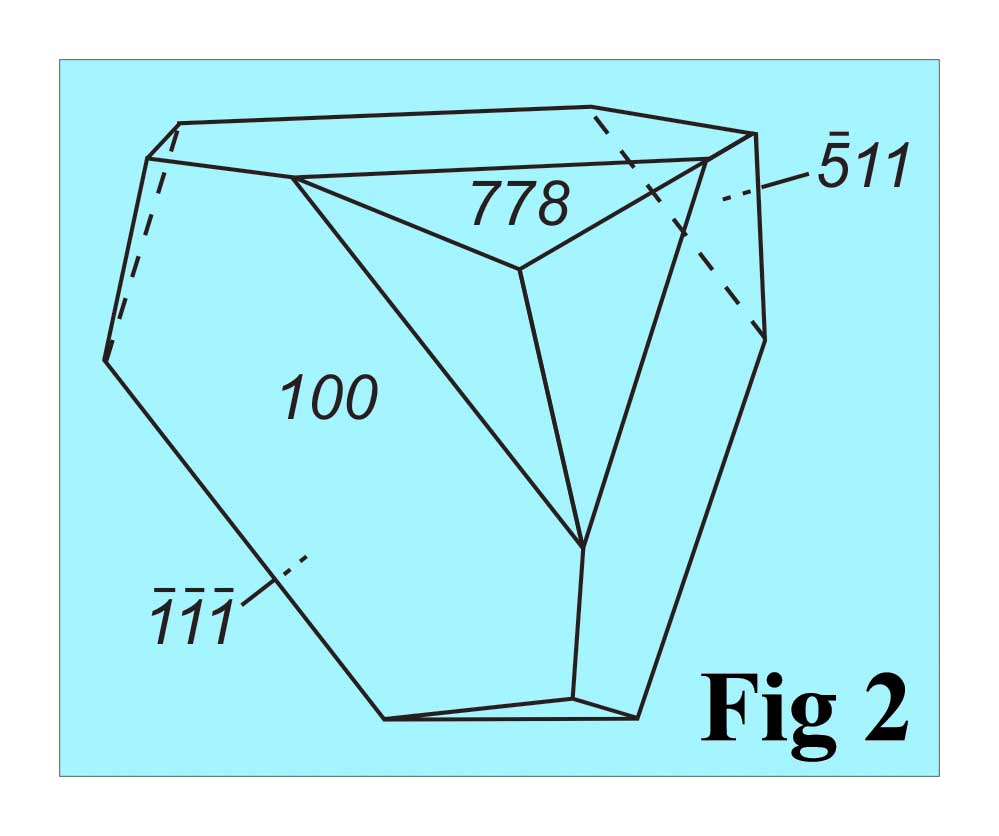

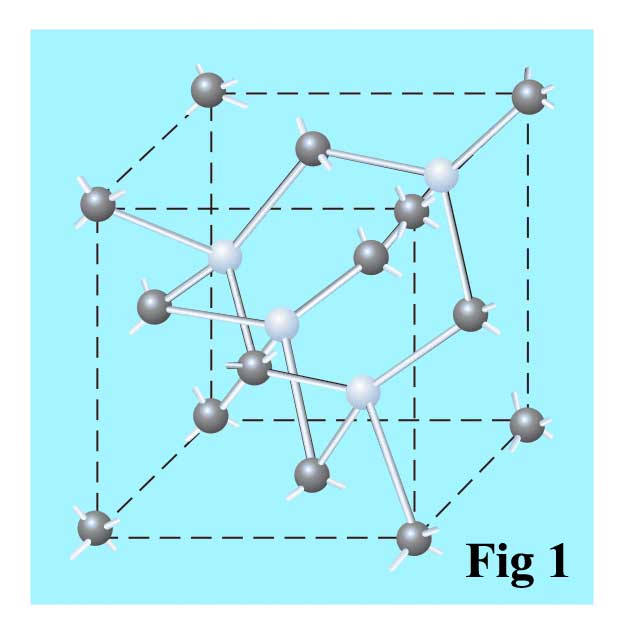

Cubic boron nitride is being characterized by a unique combination of physical-mechanical and chemical properties. Disposition of atoms in crystal grate belongs to the structural type of spharelite, which determine high density and hardness of crystals CBN. (Fig.1). As a result of breaking away crystals along the shear plane, i.e. breaking of atomic bonding, at grinding cutting edges of CBN crystals permanently renew, due to this is reached high and stable cutting ability. (Fig.2)

i.e. breaking of atomic bonding, at grinding cutting edges of CBN crystals permanently renew, due to this is reached high and stable cutting ability. (Fig.2)

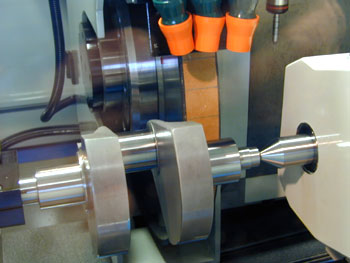

Combination of high toughness and heat resistance enables using high speeds of grinding at CBN tools. Owing to high hardness and low coefficient of friction grinding of high-speed steel with CBN tool is made with high-performance and quality result, without phase and structural changes in surface layer.

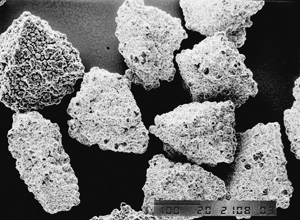

Mechanical toughness of CBN grains depends on perfection of internal structure and isometrics of grains. Modulus of elasticity of CBN (706 GPa) is significantly bigger than that of regular abrasives (296-365 GPa).

CBN products

Specific heat of CBN (670 J/kg·°C) is low than that of electrocorundum. Coefficient of linear thermal expansion of CBN is 1,5 -3 times lower than that of electrocorundum. That is why grains of cubic boron nitride have lower thermal deformation.

Chemical passivity at interaction with metals is an importantproperty of CBN, as opposed to diamond and silicon carbide it is inactive to iron, the basics of metals and iron-carbon alloy, which lowers diffusive and adhesive deterioration of grain. This excludes its gripping at interaction with treated materials, makes lower the grinding force and temperature.

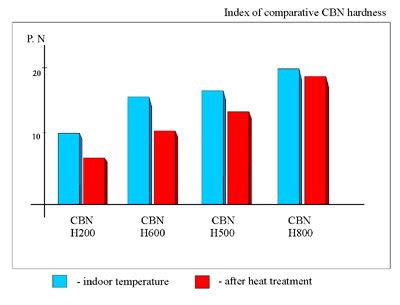

Crystals of CBN do not lose their cutting properties, phase structure and toughness till the temperature 1100-1200C°. Moreover, at temperatures of active oxidation the strength of grains is increasing, as grains are ovalized and appearing on them layers of boric anhydride B2O3 are cementing defects of surface. Formation of B2O3 layer on grains of cubic boron nitride hampers diffusion of oxygen. Obvious oxidation of CBN crystals starts at heating temperature more than 1200°C.

This excludes its gripping at interaction with treated materials, makes lower the grinding force and temperature.

Crystals of CBN do not lose their cutting properties, phase structure and toughness till the temperature 1100-1200C°. Moreover, at temperatures of active oxidation the strength of grains is increasing, as grains are ovalized and appearing on them layers of boric anhydride B2O3 are cementing defects of surface. Formation of B2O3 layer on grains of cubic boron nitride hampers diffusion of oxygen. Obvious oxidation of CBN crystals starts at heating temperature more than 1200°C.

Thus, cubic boron nitride significantly supersedes toughness, endurance, abrasive ability, thermal conductivity and chemical stability of standard abrasive materials (electrocorundum, SiC), i.e. all parameters determining quality and efficiency of instrumental abrasive materials.

i.e. breaking of atomic bonding, at grinding cutting edges of CBN crystals permanently renew, due to this is reached high and stable cutting ability. (Fig.2)

i.e. breaking of atomic bonding, at grinding cutting edges of CBN crystals permanently renew, due to this is reached high and stable cutting ability. (Fig.2) This excludes its gripping at interaction with treated materials, makes lower the grinding force and temperature.

Crystals of CBN do not lose their cutting properties, phase structure and toughness till the temperature 1100-1200C°. Moreover, at temperatures of active oxidation the strength of grains is increasing, as grains are ovalized and appearing on them layers of boric anhydride B2O3 are cementing defects of surface. Formation of B2O3 layer on grains of cubic boron nitride hampers diffusion of oxygen. Obvious oxidation of CBN crystals starts at heating temperature more than 1200°C.

This excludes its gripping at interaction with treated materials, makes lower the grinding force and temperature.

Crystals of CBN do not lose their cutting properties, phase structure and toughness till the temperature 1100-1200C°. Moreover, at temperatures of active oxidation the strength of grains is increasing, as grains are ovalized and appearing on them layers of boric anhydride B2O3 are cementing defects of surface. Formation of B2O3 layer on grains of cubic boron nitride hampers diffusion of oxygen. Obvious oxidation of CBN crystals starts at heating temperature more than 1200°C.